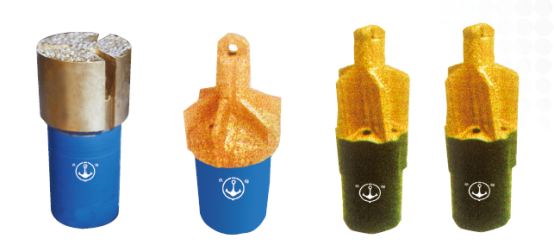

The mill shoe include flat-bottom mill shoe, concave-bottom mill shoe, tapered bottom mill shoe, pilot mill shoe,pear–shaped mill shoe, washover shoe, high effective cone mill shoe. The flat-bottom mill shoe is a normal tool for grinding downhole small catches and repairing the fish top. The concave-bottom mill shoe is used to grind downhole small objects and other unstable fallen objects.The pilot mill shoe is used to grind the fallen objects which are with internal hole and shaking downhole. The tapered bottom mill shoe is used to repair and maintain small deformed location and clean wall sundries.

Technical parameters and specifications for flat-bottom , concave-bottom , tapered bottom , pear–shaped mill shoe

O.D.(mm) | Thread connection | Suitable hole size (mm) |

89 | NC26, 2 3/8REG | 95.2~101.6 |

97 | 107.9~114.3 | |

110 | NC31, 2 7/8REG, 3 1/2REG, | 117.5~127.0 |

121 | 130.0~139.7 | |

130 | 142.9~152.4 | |

140 | NC38, 3 1/2REG, 4 1/2REG, | 155.6~165.1 |

156 | 168.0~187.3 | |

178 | 190.5~209.5 | |

200 | NC50, 4 1/2REG, | 212.7~241.3 |

232 | 244.5~269.9. | |

257 | 6 5/8REG, | 273.0~295.3 |

279 | 298.5~317.5 | |

295 | 320.6~346.1 | |

330 | 349.3~406.4 | |

381 | 406.4~444.5 | |

406 | 7 5/8REG, | 431.8~508.0 |

432 | 457.2~533.4 | |

534 | 558.8~660.0 | |

686 | 711.2~863.6 |

Technical parameters and specifications for pilot mill shoe

O.D.(mm) | O.D. of the milled tube(mm) | Wing length (mm) | Thread connection | Suitable hole size (mm) |

97 | 73–89 | ≥ 150 | NC26 | 107.9~114.3 |

121 | 90–102 | NC31, 2 7/8REG, 3 1/2REG, | 130.0~139.7 | |

130 | 100–160 | ≥ 200 | 142.9~152.4 | |

140 | 110–120 | 155.6~165.1 | ||

156 | 127 | 3 1/2REG, | 168.0~187.3 | |

178 | 158–168 | 4 1/2REG | 190.5~209.5 | |

200 | 168–178 | 212.7~241.3 | ||

232 | 194 | 244.5~269.9 | ||

257 | 210–219 | ≥ 250 | 6 5/8REG | 273.0~295.3 |

279 | 220–230 | 298.5~317.5 | ||

295 | 240–246 | ≥ 300 | 320.6~346.1 | |

330 | 273 | 349.3~406.4 | ||

381 | 320 | 406.4~444.5 |

Technical parameters and specifications for washover shoe

O.D.(mm) | I.D.(mm) | Length (mm) | MIn-Hole size (mm) | Max washover string (mm) |

117 | 99.57 | 500– 1000 | 120.65 | 88.90 |

136 | 108.61 | 146.05 | 101.60 | |

145 | 124.26 | 155.58 | 120.65 | |

121.36 | 155.58 | 117.48 | ||

118.62 | 155.58 | 114.30 | ||

177 | 150.39 | 187.33 | 142.88 | |

190 | 159.41 | 200.03 | 152.40 | |

202 | 174.63 | 212.73 | 168.28 | |

171.83 | 212.73 | 165.10 | ||

168.28 | 212.73 | 161.93 | ||

205 | 184.15 | 215.90 | 177.80 | |

209 | 187.58 | 219.08 | 180.98 | |

234 | 198.76 | 244.48 | 190.50 | |

193.68 | 244.48 | 187.33 | ||

240 | 207.01 | 250.83 | 200.03 | |

256 | 224.41 | 266.70 | 215.90 | |

220.50 | 266.70 | 212.73 | ||

288 | 252.73 | 298.45 | 244.48 | |

247.90 | 298.45 | 238.13 | ||

313 | 276.35 | 323.85 | 266.70 | |

273.61 | 323.85 | 263.53 | ||

355 | 317.88 | 365.13 | 307.98 | |

434 | 381.25 | 444.50 | 368.30 | |

498 | 448.44 | 508.00 | 438.15 | |

574 | 525.65 | 584.20 | 479.43 |